As we all know, refrigerated vehicles are mainly composed of chassis, truck refrigeration system, and thermal insulation compartments. They are mainly used to transport temperature-sensitive food, such as frozen meat, vegetables and fruits. Multi-temperature zone refrigerated trucks are designed to take fully consideration of the characteristics of this kind of transportation. We can say that refrigerated vehicles occupy a certain proportion of short- and medium-distance logistics distribution.

Key Role of Refrigeration Unit in Maintaining the Desired Temperature of Perishable Goods

The refrigeration system is a critical part in the entire cold chain transportation. The refrigerated goods are very different from other ordinary goods . They have extremely strict requirements on temperature.

Therefore, when it comes to choose transport refrigeration units, you must have sufficient knowledge and understand the refrigeration manufacturer - your future business partner very well. Besides that, it is necessary to communicate with the supplier timely how to deal with some emergency situation.

In addition, when loading, you must first measure the temperature of the loaded goods. If the set point temperature of refrigeration unit kit is higher or lower than that of the cargoes, it is difficult to reach the temperature required for safe land delivery. The storage temperature of the frozen cargoes must be consistent with the transportation temperature. If its temperature changes frequently, the moisture will be lost, which will cause the quality of your products to change, and shorten the shelf life of the goods.

Types of Refrigerated Truck Refrigeration Unit

Truck refrigeration units are generally divided into two types.

One is independent refrigeration system;

It has a separate power source(an independent auxiliary engine, generator, and refrigeration compressor) and is able to operate independently. The operation state of the main engine has no effect on that of the transport refrigeration unit.

The purchase cost of independent refrigeration system is high. Therefore, those who are with insufficient budget can choose to buy split truck refrigeration unit which is low in investment.

the other is non-independent refrigeration unit;

Non-independent refrigeration units need to rely on the engine to drive the compressor to run, and there is no separate power unit to provide a source of power.

Selection of Refrigerated Truck Refrigeration Unit

According to the required temperature of cargoes transport, deep-frozen unit (also called as freezer unit) or chiller unit can be selected. From the point of view of price, deep-frozen truck unit is much more expensive than chiller systems as they can maintain the interior compartment temperature as low as -30℃. What should be noticed is that truck chiller units always have no defrost function.

So, how should the truck refrigeration unit be selected?

1. Box Truck Length

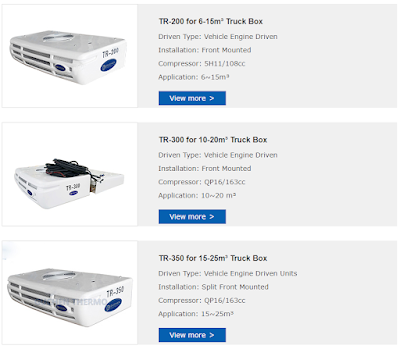

Due to the different requirements of cold chain transportation, there are different truck models and compartments available in the market. A refrigeration unit is not universal, and not suitable for all models.

If your truck body is below 6m with a volume in the range of 4-31m³, direct drive (nonindependent) refrigeration unit is a good alternative.

For refrigerated trucks with a body more than 6m, diesel powered (independent) refrigeration unit should be selected. Different refrigeration systems are with different cooling capacity which will directly affect its final refrigeration effect. Large truck model should be installed with a TRU with large cooling capacity.

In addition, there are different installation methods, such as rooftop installation, front mounted installation, to better adapt to the refrigerated vehicles.

2. Temperature requirements

Different goods have different temperature requirements, for example, the temperature setting of ice cream transportation should be -5° to -15°. Different temperatures correspond to different powers. When choosing a refrigeration unit , You can choose the suitable power according to the temperature demands.

Tip: Pre-cooling

You need to pre-cool the refrigerated truck. This step is very important. Under normal circumstances, it may take one hour and a half to pre-cool your truck cargo compartment.

3. Transport distances

Independent refrigeration units and non-independent ones have different power sources. Transport distance and time required for cold chain transportation should be considered when choosing a suitable system. Non-independent refrigeration units are suitable for short-distance transportation, and independent refrigeration units are more suitable for long-distance transportation. Choosing refrigeration units according to distance and time can save more power costs.